Propellers and Governors

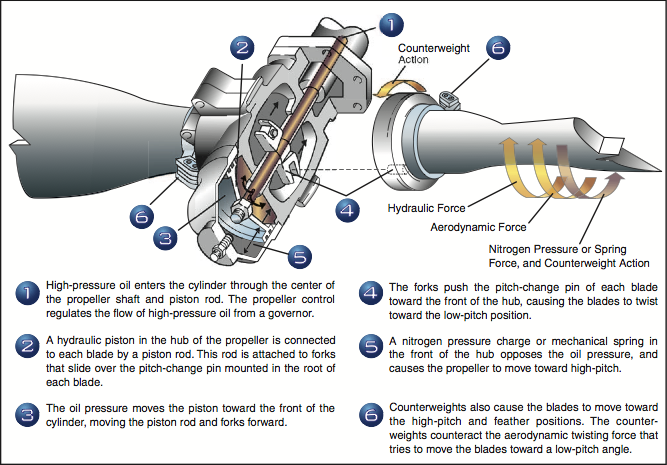

The propeller governors of a twin-engine airplane works like that of a complex single-engine plane, but in reverse. In a twin engine, oil pressure is used to turn the blades to low pitch (high RPM) so that if oil pressure is lost, the pilot can feather the engine to reduce drag, as previously discussed.

Propeller Governor

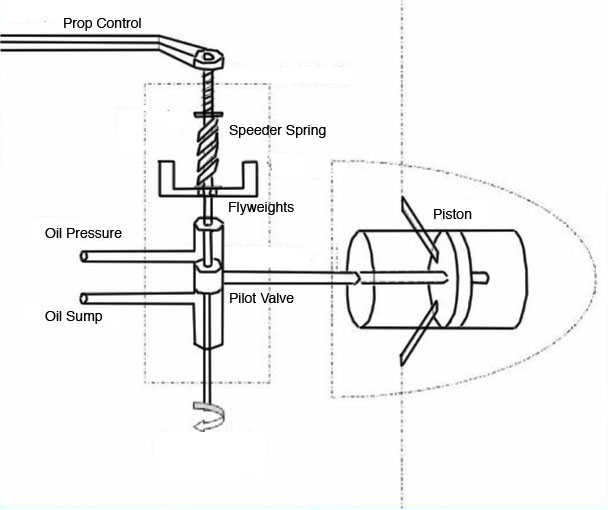

A constant-speed propeller uses a governor to control the RPM of the engine. It does so with the help of mechanical linkage from the propeller control knob/lever to a speeder spring, centrifugal flyweights, and a pilot valve with allows the flow of oil either from or to the oil sump.

The propeller control in the cockpit compresses or relaxes the speeder spring, which affects the force exerted on the flyweights. As those move either out or in, the mechanical linkage to the pilot valve causes it to move in a direction which allows oil to flow either into or out of the propeller hub, moving a piston, which forces the blades to higher or lower pitch.

On Speed Condition

In this condition, the centrifugal force on the flyweights is equal to the force of the speeder spring. Thus the pilot valve is neutral, closing off both the oil sump and pressure lines, allowing no oil to flow to or from the propeller hub.

Over Speed Condition

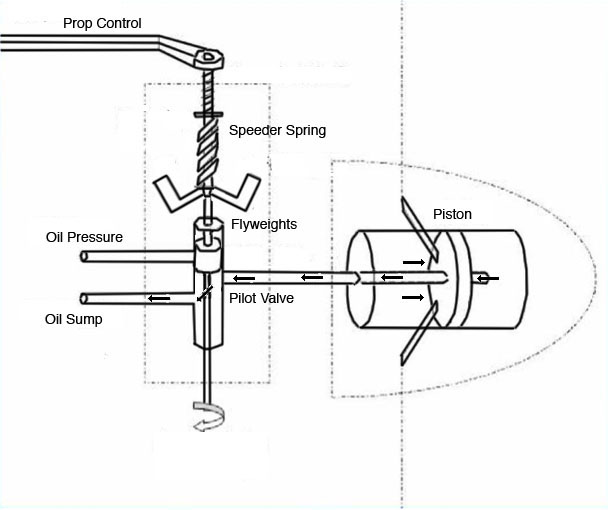

As the propeller speeds up, the increased centrifugal force causes the flyweights to move out, forcing the pilot valve to rise. This opens the path back to the oil sump, which accepts oil from the propeller hub, decreasing RPM. As the propeller slows to the proper speed, the decreased centrifugal forces on the flyweights move them back to neutral and the pilot valve moves in conjunction closing off the oil pressure and sump lines.

Under Speed Condition

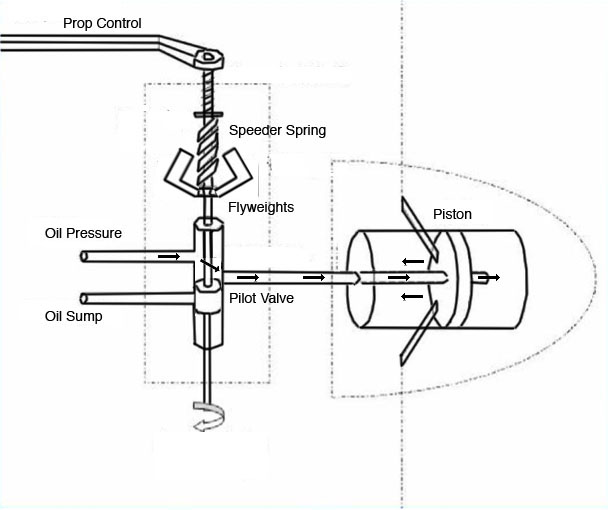

As the propeller slows down, the decreased centrifugal force causes the flyweights to move in, forcing the pilot valve to drop. This opens the way for the oil pressure line to force oil into the propeller hub, thus increasing the RPM of the propeller. As the propeller speeds up to the proper RPM, the increased centrifugal forces on the flyweights move them back to neutral and the pilot valve moves in conjunction closing off the oil pressure and sump lines.

Off the Governor

At lower manifold pressure settings, the propeller may go "off the governor", which simply means the engine isn't producing enough power to allow the governor to properly regulate the RPM. In this state, the flyweights will be deflected fully inward, and the propeller now acts as if it were fixed pitch. The governing range is generally indicated by the green band on the manifold pressure gauge.

Multi-Engine Propeller Considerations

Feathering

To fully feather the propeller, the propeller control is brought fully aft. All oil pressure is dumped from the governor to the oil sump, and the counterweights drive the propeller towards feather. So if oil pressure leaving the governor pushes blades toward feather, why do the propellers not feather on engine shutdown?

The answer is there are lock pins in the propeller hub which prevent feathering below 7-800 RPM to prevent the propeller from feathering during start and shutdown. During normal operations, centrifugal force retracts the locks, allowing the propeller to feather, but you must remember to feather a failed engine before the locks engage. Both feathering and starting a feathered engine are not recommended due to excessive stress and vibrations generated.

To start a feathered engine in flight, the pilot moves the prop control out of feather to release this pressure. Once oil flows into the governor, the blades are driven towards high RPM (low pitch) and the propeller begins to windmill.

You may also encounter unfeathering accumulators on some multi-engine airplanes. These aid substantially in starting a feathered engine by storing oil under pressure (typically compressed air or nitrogen) and releasing it into the propeller hub which forces the blades out of feather.

Propeller Synchronizing

Out of sync propellers cause an unpleasant wharbling or vibration in the cockpit of a multi-engine airplane. Aside from your hands and ears, there are systems which can be used to synchronize the propellers and minimize or reduce this effect.

- Synchronizer - Uses frequency signals to control boxes driving electric motors to sync engine RPM

- Synchrophaser - Acts like a synchronizer to precisely match RPM, but it also compares and adjusts the positions of the individual blades in their arcs.

- Synchroscope - A small, black and white, wheel located in the instrument panel which spins counterclockwise when the left engine is faster than the right and vice versa